Combustors

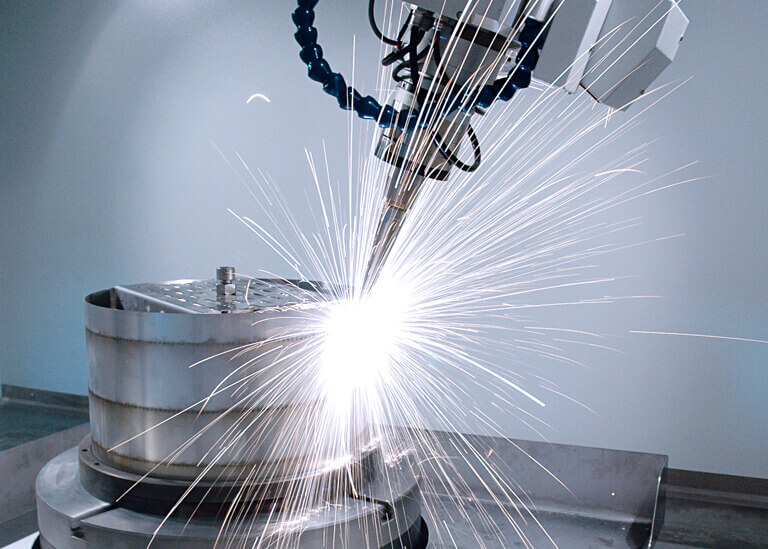

Winbro offers a range of cooling hole solutions for aero and industrial turbine combustors.

Combustor cooling is achieved in two primary forms, wall and effusion cooling, with some combustors making use of both forms. In general a wall cooled combustor will have fewer holes of a greater diameter and use of the shape of the combustor to facilitate effective cooling. By comparison, an effusion cooled combustor has many thousands of small holes acutely angled to the side wall of what is essentially a conically form.

The materials used to manufacture these components, generically known as super alloys, include elements of nickel, cobalt, or nickel-iron. These high performance alloys rely heavily on the chemical and other non-conventional machining processes, for which Winbro has become renowned as a world leader.

GO BACK