MF400

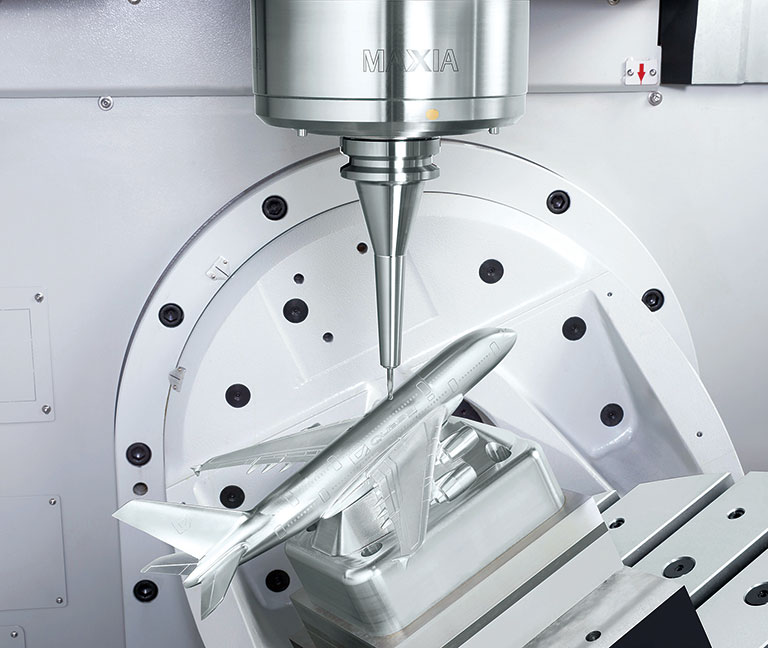

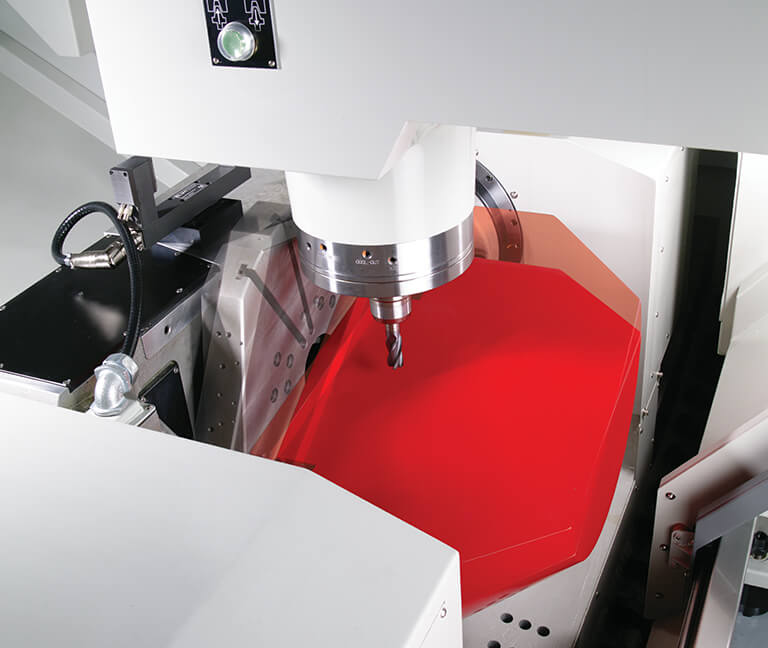

The high performance MF series multiple face / 5-axis vertical machining centers are for small to medium complex high-quality parts for aerospace, automotive, medical, mold and die applications. From roughing to finishing, the MF series reduces setup time and overall production, while improving machining accuracy, quality and precision.

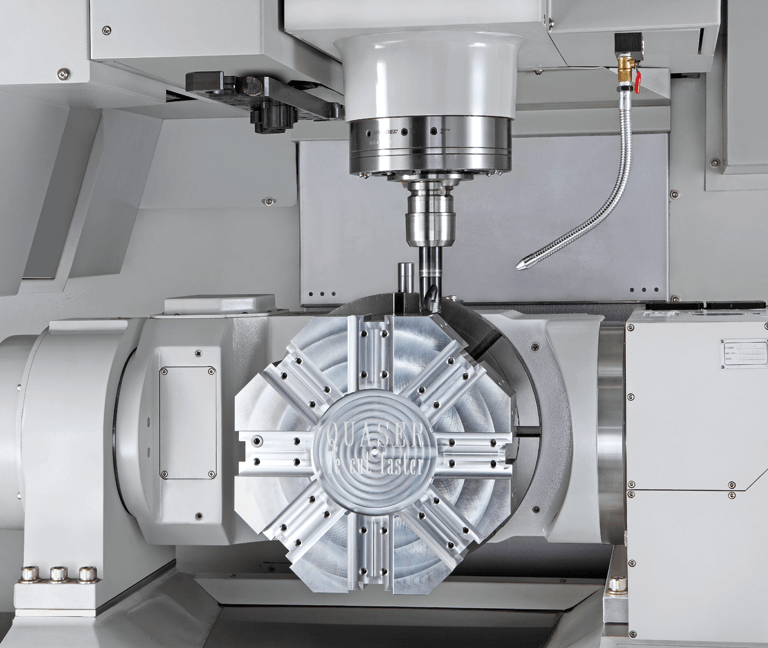

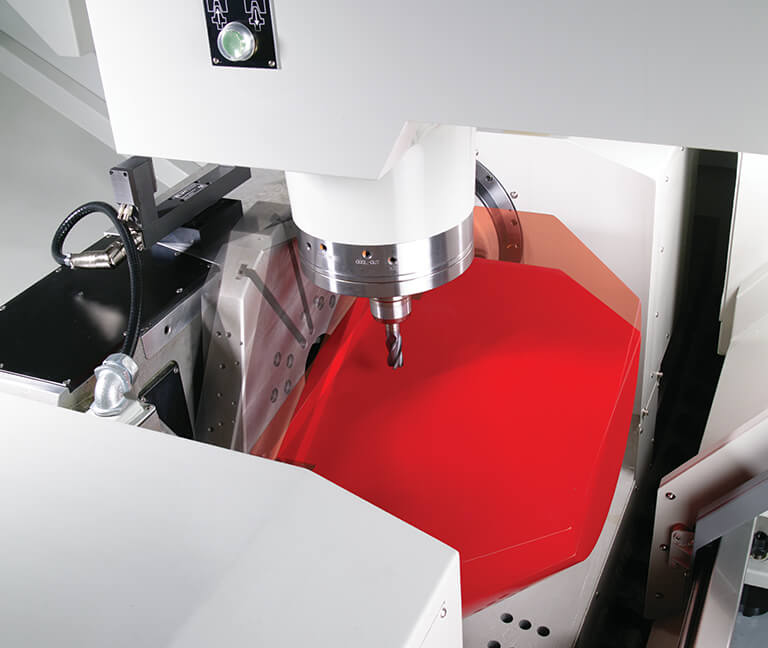

The rotary table is designed to reduce coefficient of friction and strengthen the torque transmission capability of the drive motor.

The symmetrical structure of slide mechanism and rotary pallet allows for higher rigidity.

The MF series is designed for easy operation, even for beginners who have no experience of multiple face/5 axis machining.

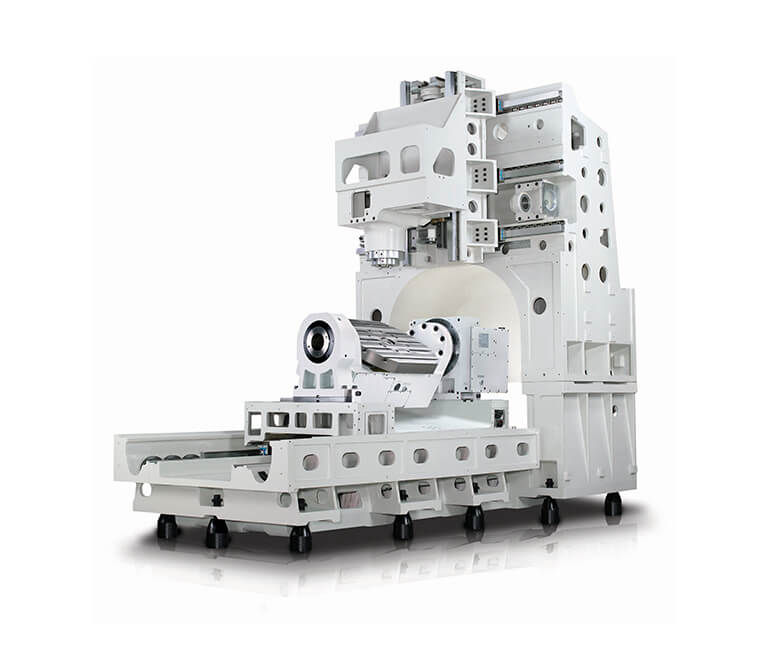

MF700

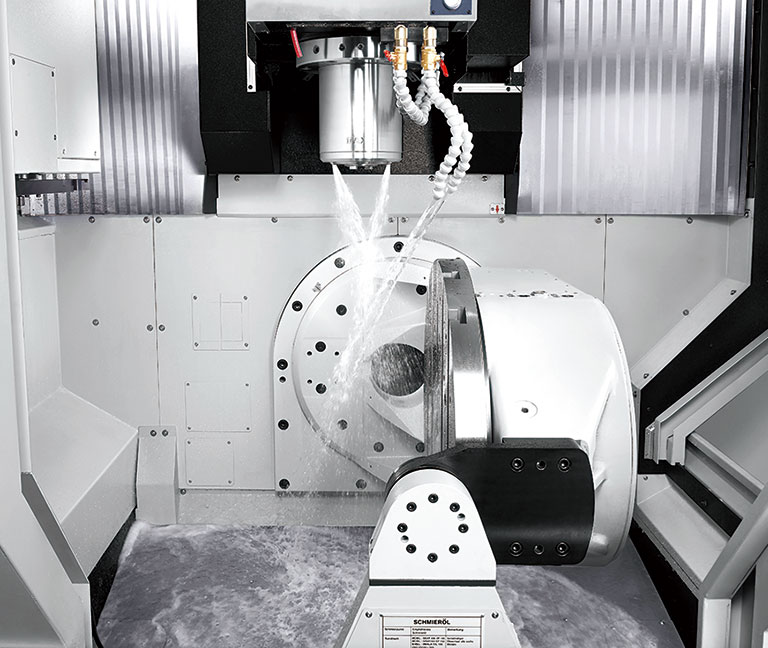

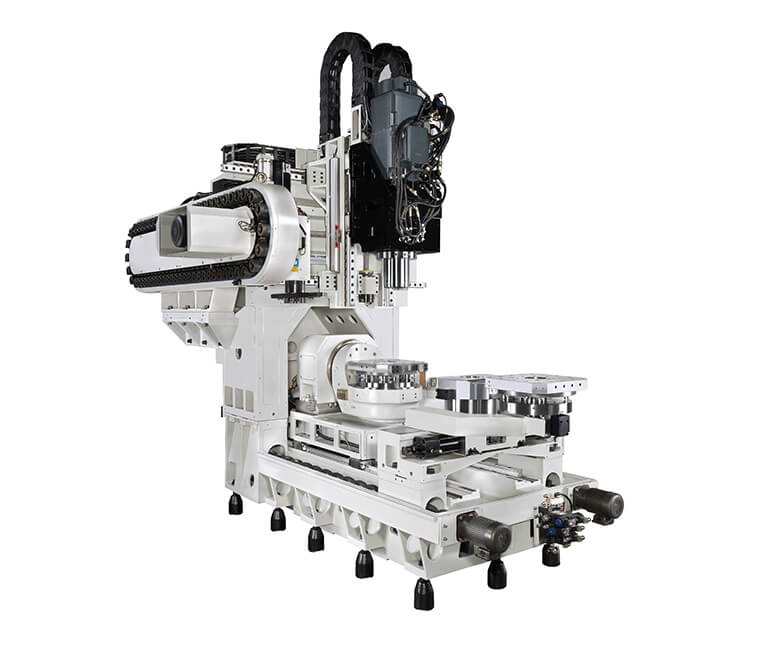

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

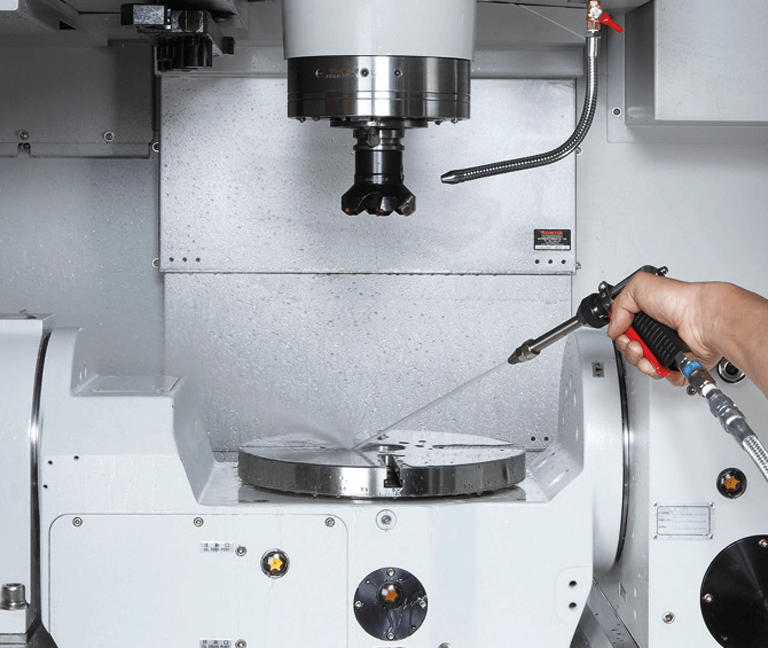

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.

UX500

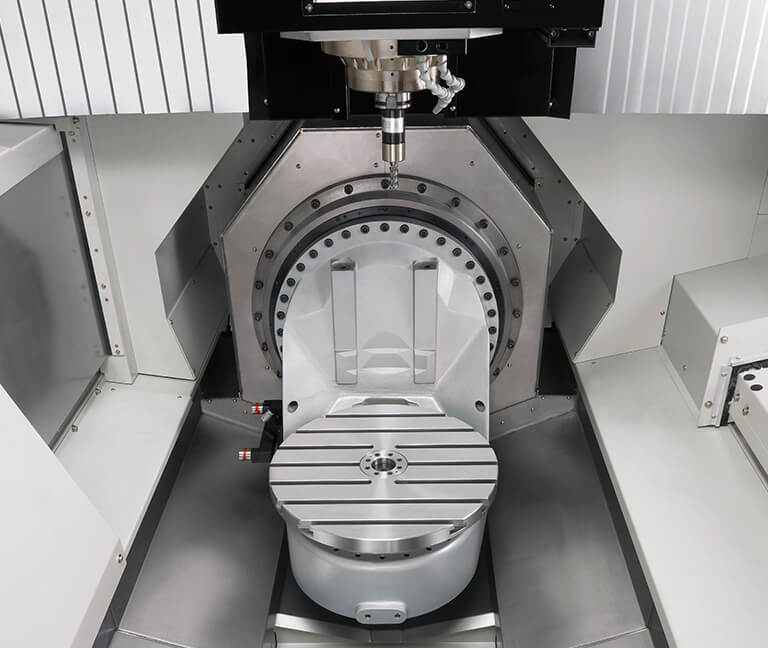

This single unit machine features high rigidity, accuracy, and efficiency and offers a high ease of operation with a relatively compact footprint.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The modular design allows for expandable multi-pallet configurations.

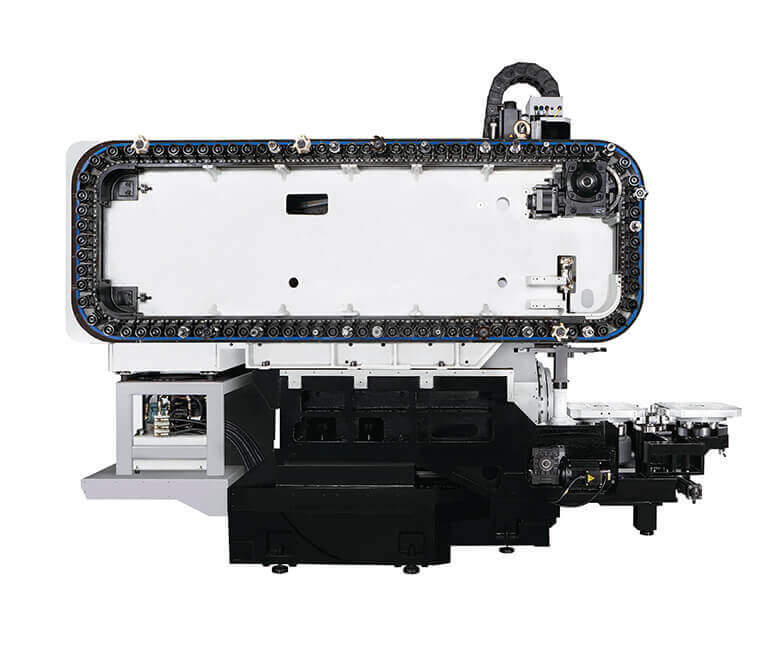

UX500APC

UX500APC is a highly versatile five-axis VMC with automatic pallet changer.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The dual work zone design can reduce the machine down time due to the workpiece load / unload to increase the utilization rate.

The UX500APC is modular and expandable: End users can expand the number of work pallets and tools according to the machining demand.

UX630

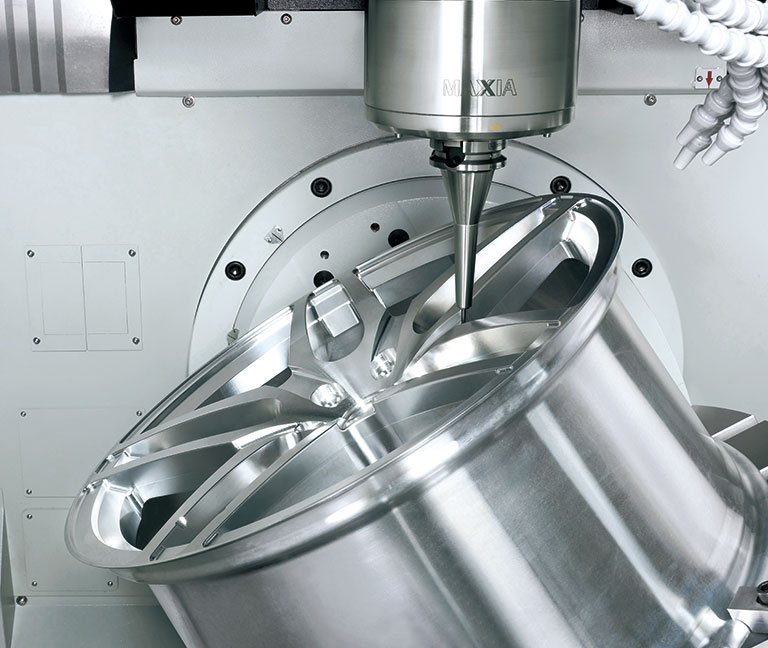

The UX630 with a B-axis +/- 120 degrees, X-axis 900mm working stroke can meet the high demand of the diversity and the flexibility of five-axis machining.

Centralized lubrication and air pressure plate are well located to make machine maintenance easy.

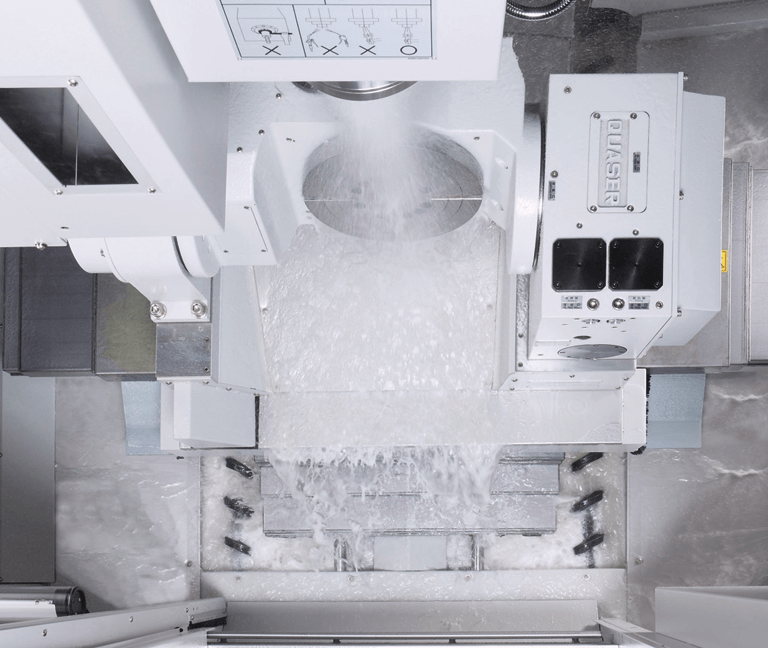

The chips are discharged directly through the high-efficiency chip conveyor under the machine table, and the chips are discharged quickly, in large quantities, saving machine maintenance time.

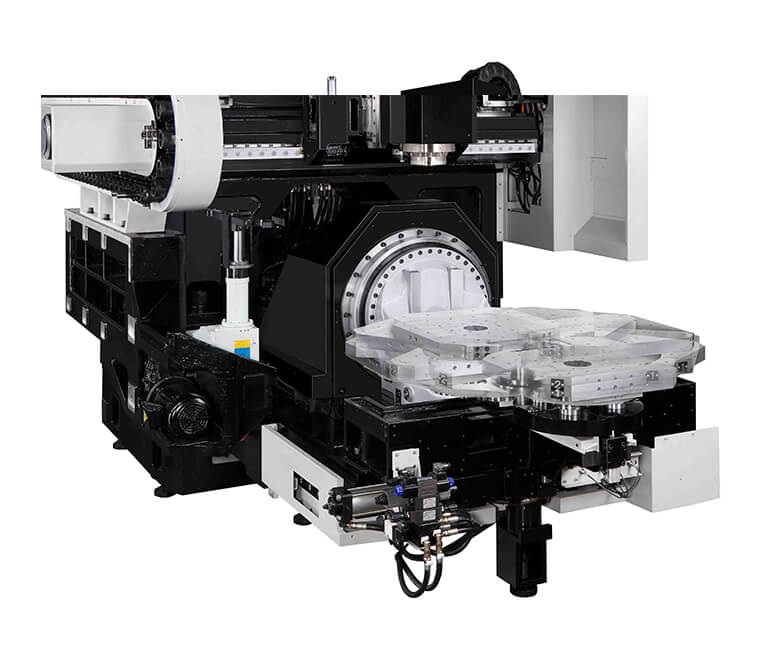

UX630APC

The UX630APC table allows for heavy loading: up to 500kg with maximum swing of 630mm and height 480mm to meet the demands of medium size work piece for 5 Axis simultaneous machining.

Compact design with excellent accessibility allows the operator to easily reach the work piece and spindle to adjust tools and conduct workpiece measurement. The automatic pallet changer mechanism (APC) minimizes the machine’s standstill time to enhance machine productivity.

UX600C

The double column structure design emphasizes excellent performance in terms of accuracy, mechanical rigidity, and machining stability.

Stable and compression-resistant design to ensure the spindle torsion, cutting ability, and worktable load.

Due to our outstanding craftsmanship, our machine has better cutting performance and better machining accuracy than most competitors’ in its class.

UX600P

The double column structure design emphasizes excellent performance in terms of accuracy, mechanical rigidity, and machining stability.

Stable and compression-resistant design to ensure the spindle torsion, cutting ability, and worktable load.