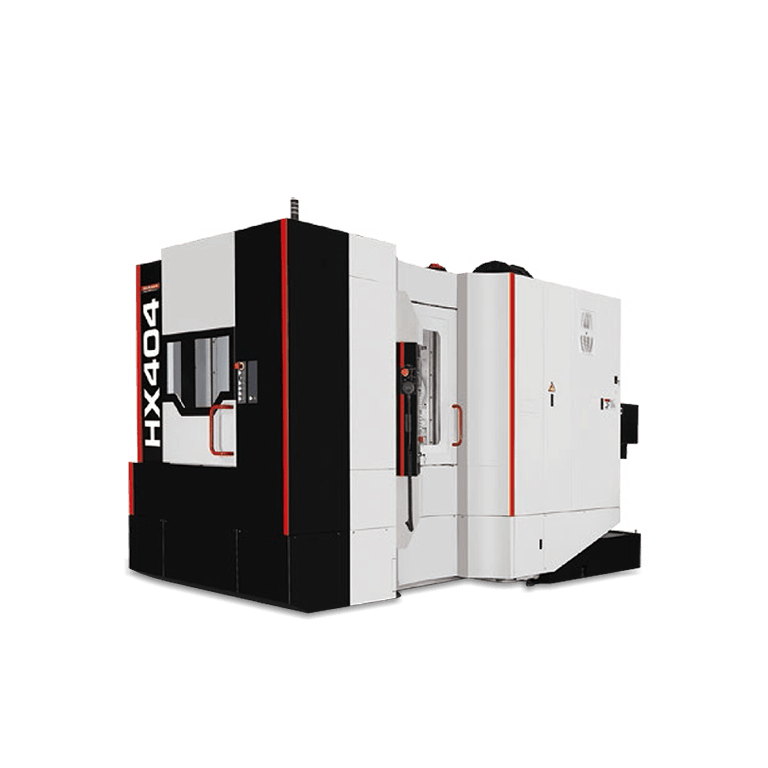

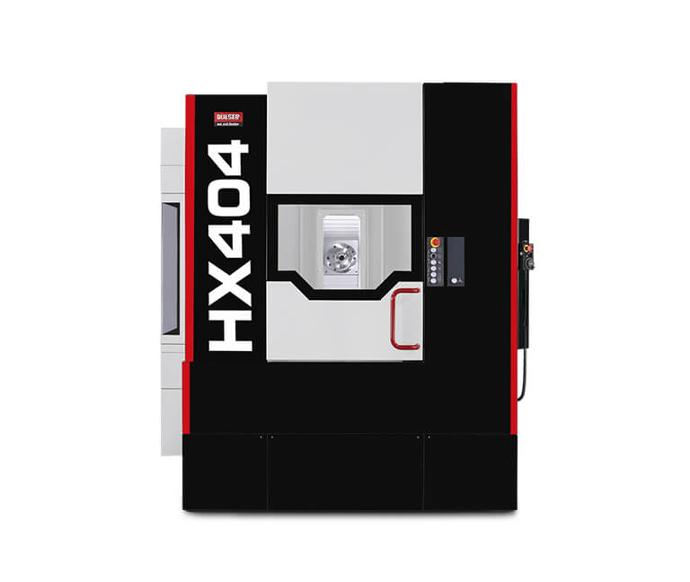

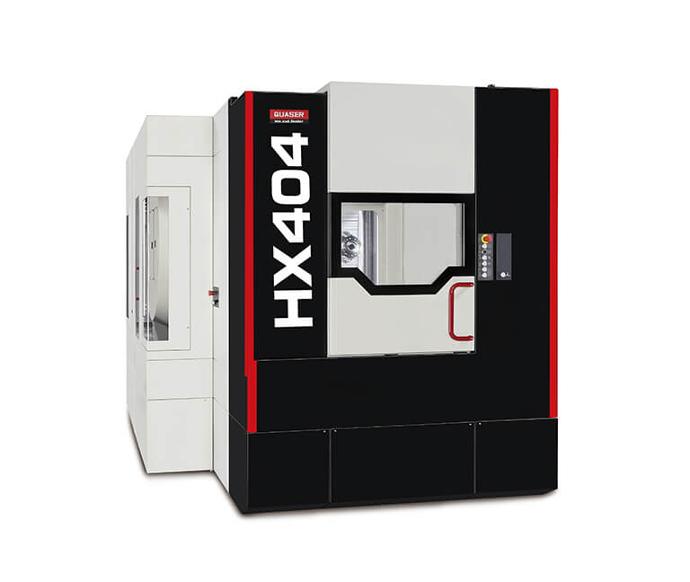

HX404

Horizontal M/C

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Technical Data | HX404 |

| Work Range | |

| Pallet Size | □400 mm (15.8") |

| Max. Work Swing Diameter | Ø630 mm (Ø24.8") |

| Max. Work Piece Height | 900 mm (35.4") |

| Travel X | 560 mm (22.1") |

| Travel Y | 640 mm (25.2") |

| Travel Z | 640 mm (25.2") |

| B Minimum Indexing (Degree) | 1/0.001 |

| Table Load Capacity | 400 kg (882 lbs) |

| Pallet Changer | |

| Number of Pallet | 2 |

| Method of Pallet Changer | Arm type |

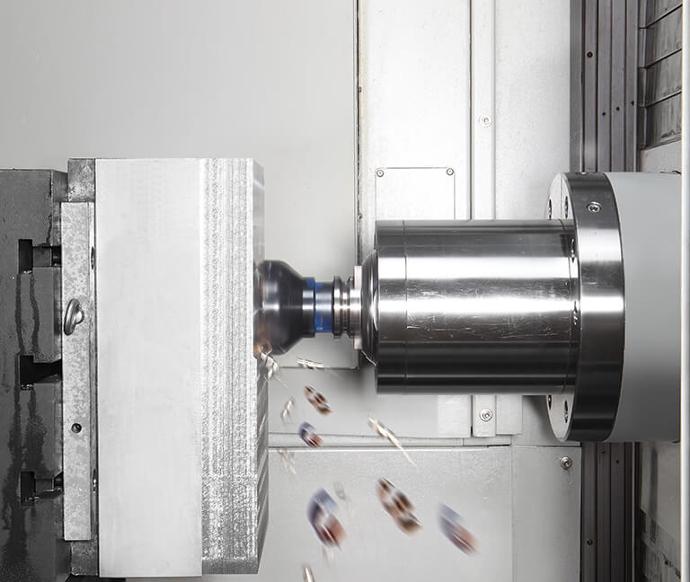

| Main Spindle | |

| Spindle Taper |

40 taper

|

| Max. Spindle Speed | 12K ~ 20K |

| Tool Changer | |

| Magazine Positions | 60 (std.) |

| Max. Tool Diameter | 76.2 mm (3") |

| Max. Tool Dia. Due to Neighbor Pots Are Empty | 125 mm (4.92") |

| Max. Tool Length | 350 mm (13.78") |

Applications

HX404 is widely applied to high standard industries, such as automobile, aerospace, mechanical parts…and so forth. More importantly, in response to automation, it is able to combine with multi-pallet and larger tool magazine to increase productivity efficiency and lower labor cost to make the best resources allocation.