Technologies

EDM

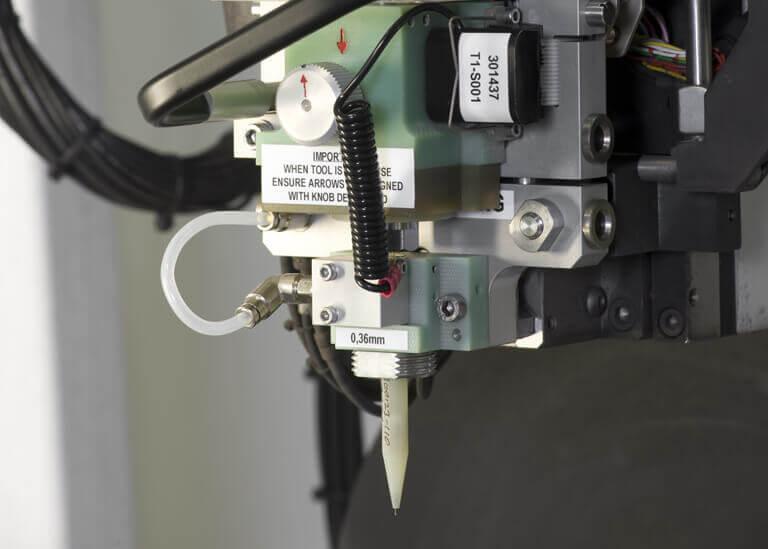

Winbro Group Technologies HSD or FHD (Fast Hole Drilling) technology differs significantly from the conventional EDM process, using de-ionised water as the dielectric medium which is then delivered to the machining gap via tubular brass electrodes.

Winbros’ process delivers substantially faster drilling times than the conventional oil dielectric process and has since been adopted as the primary process for the production of cooling holes in turbine blades throughout the world. Winbro is widely recognised as the leader in the development and application of this process across the turbine engine market.

Winbro specialises in the manufacture of six (6) axes machining systems which can not only drill with single electrodes, but with up to 45 electrodes simultaneously.