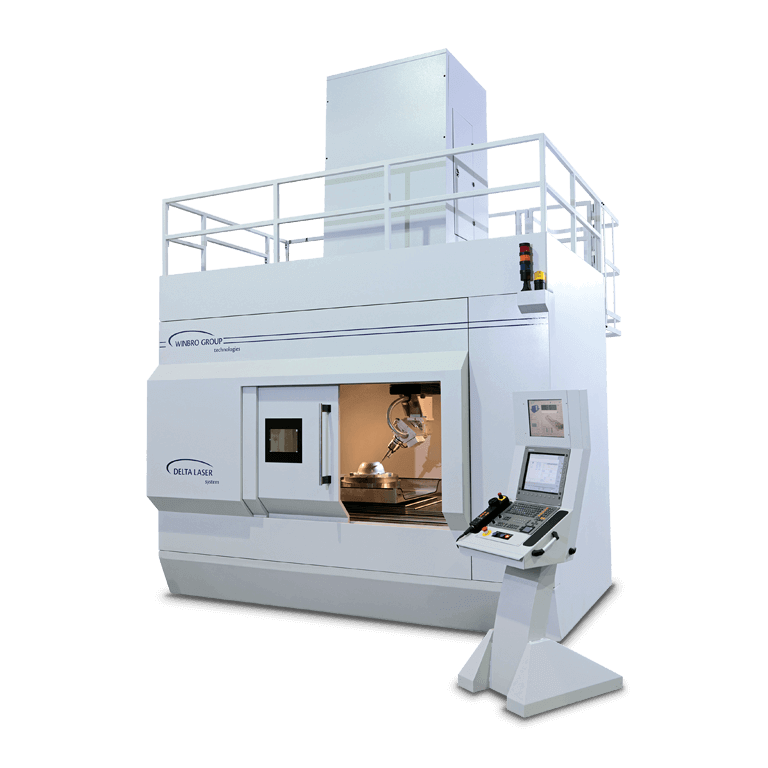

Delta Laser

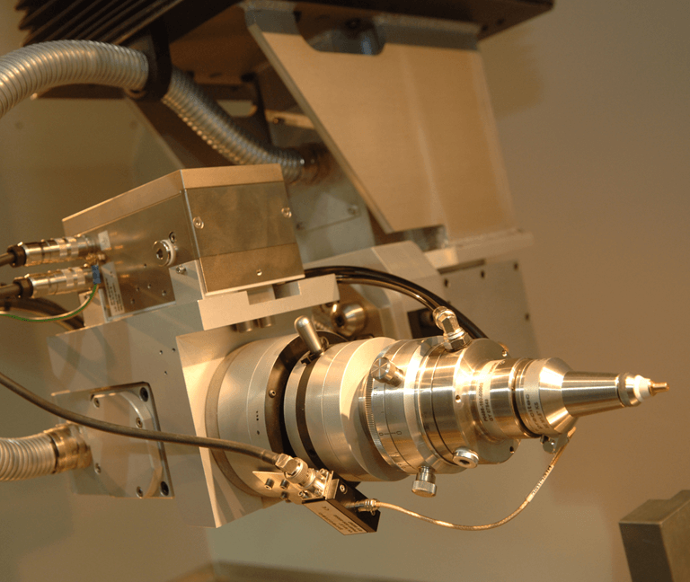

LASER

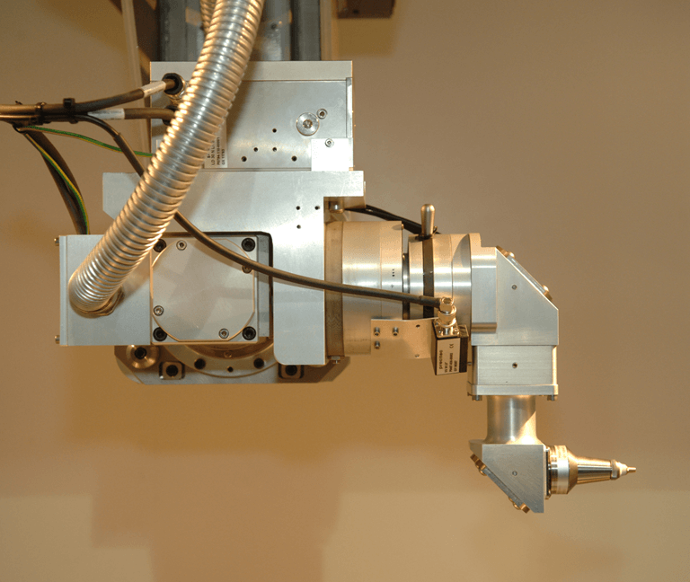

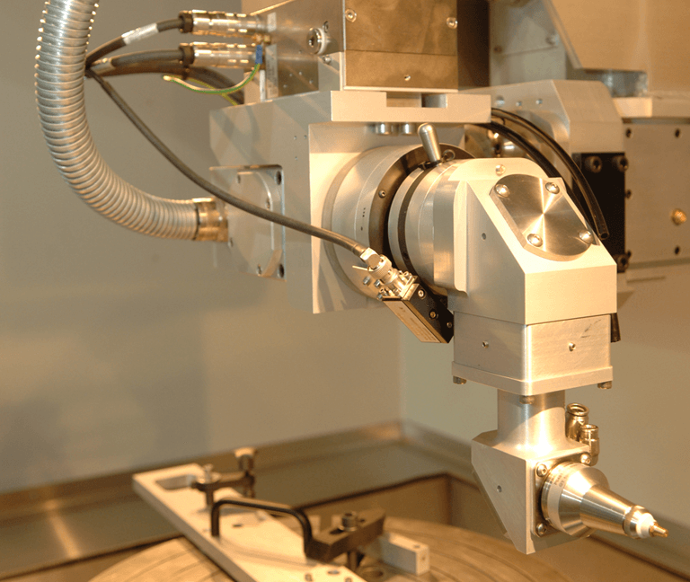

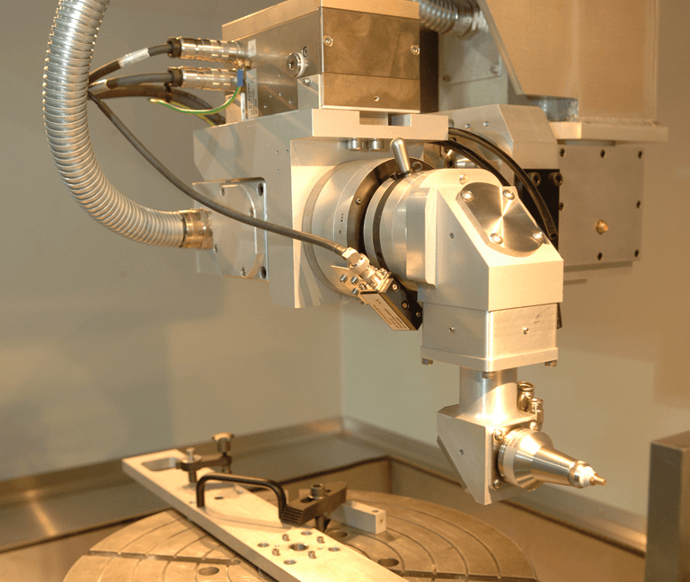

Built upon a substantial, single piece base and with a machine capacity of 1,900mm (74.8 inches) diameter and 900mm (35.4 inches) in height, the Delta laser machining system is designed for large Aero or IGT omponents with a combined component and fixture weight of up to 500kg (1100 lbs).

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Type | Delta Laser |

| Strokes | |

| X | 1,500mm (59 inches) |

| Y | 750mm (29.5 inches) |

| Z | 1,000mm (39.4 inches) |

| Rotary B | +/- 140° |

| Rotary C | Continuous |

| Accuracy | |

| Linear | 0.015mm (0.0006 inches) |

| Rotary | 15 arc sec |

| Repeatability | |

| Linear | 0.010mm (0.0004 inches) |

| Rotary | 10 arc sec |

Applications

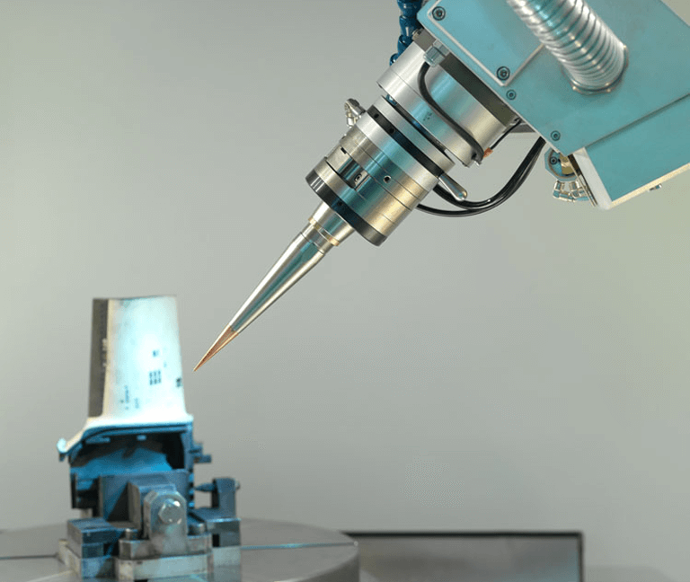

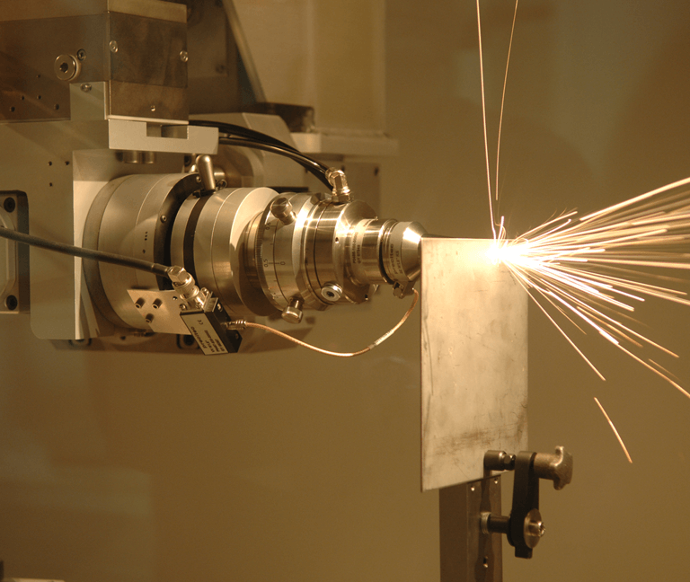

A robust design combined with multi-axis flexibility, large work envelope and a choice of laser type means that the Delta can be used for many different applications including:

- Percussion Drilling

- Drilling on the Fly

- Hole Cutting (Trepanning

- 2D and 3D Shaped Hole Machining (Ablation or Vectoring)

- Ceramic Coating Removal - Ablation

- 3D High Speed Cutting

- Cladding for Repair and Overhaul

- Welding

- Combination of these processes using dual laser sources on a single machine

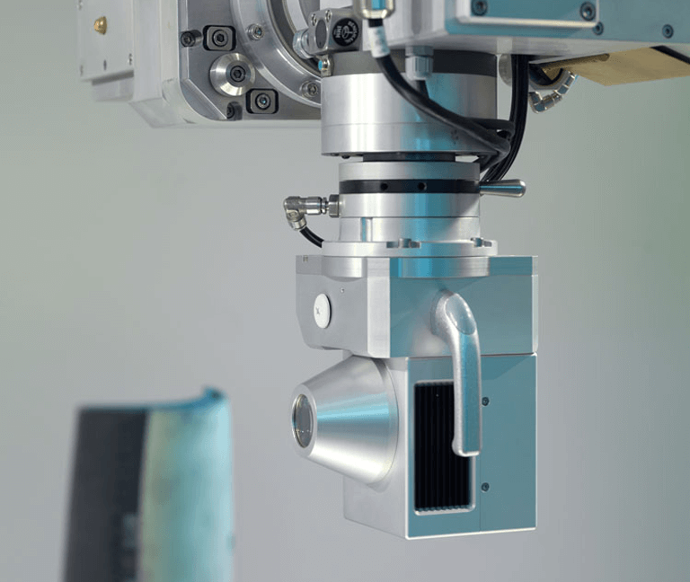

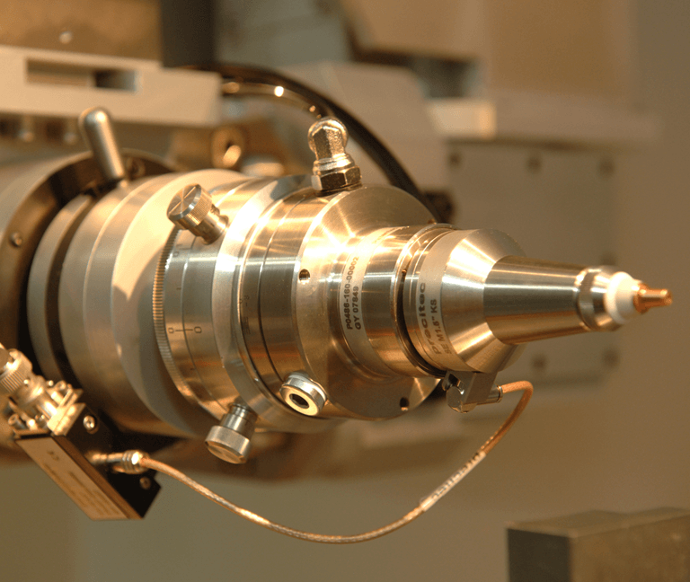

Features

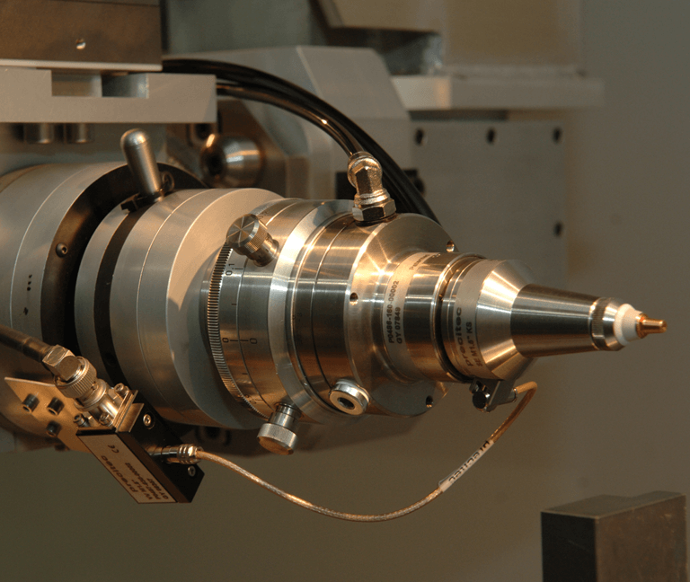

01

Advanced programming interface (LFE) from user’s CAD output

02

Heidenhain iTNC530 control

03

Tool tip interpolation

04

Crash protection

05

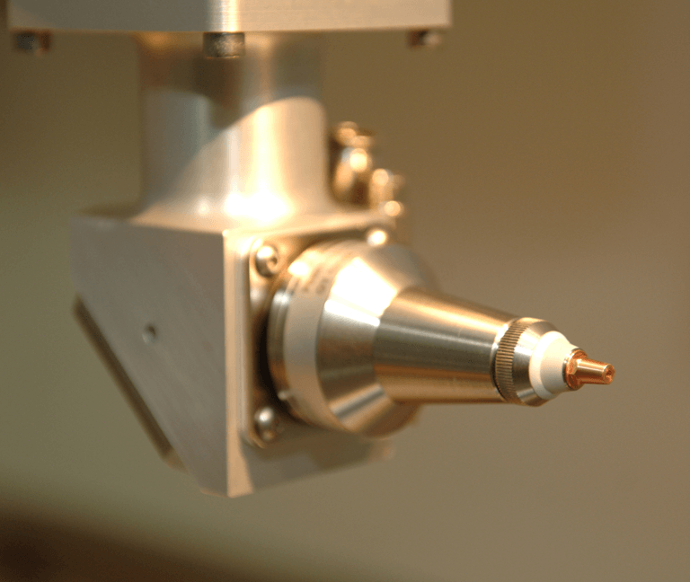

Quick change nozzle system

06

Break through detection

07

Contact and non-contact probing

08

Patented 6 point probing system

09

Capacitive focus control

10

Component mapping