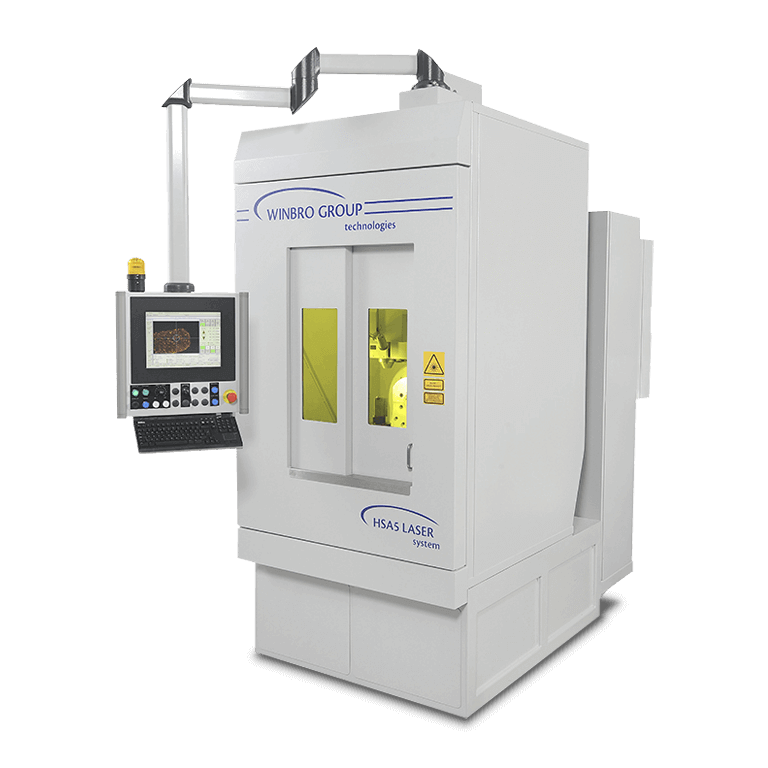

HSA5

LASER

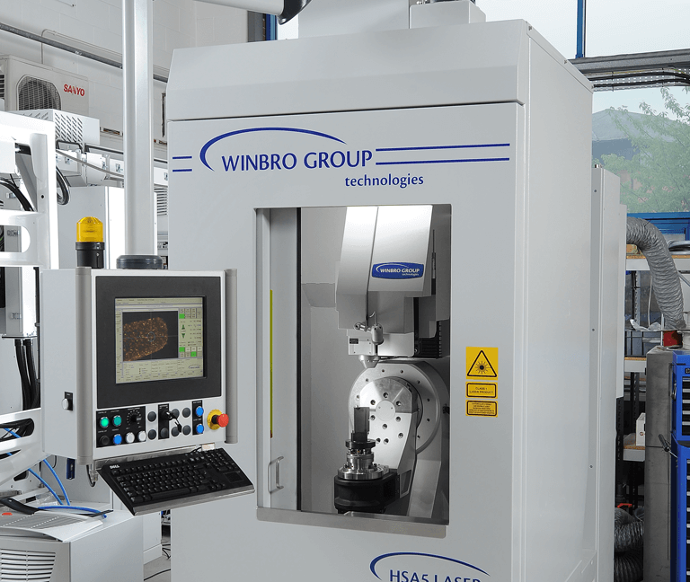

The HSA5-III machine incorporates features specifically developed for intricate laser processing of cooling hole features in components such as blades, vanes and segments in Aero and Industrial gas turbines.

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Type | HSA5 |

| Axis Travel | |

| X Axis | 200mm (7.8 inches) |

| Y Axis | 200mm (7.8 inches) |

| Z Axis | 250mm (9.8 inches) |

| A Axis | Continuous |

| B Axis | - 135° / + 100° |

| Speed | |

| X,Y and Z axes | 10m/min (390ipm) |

| A axis | 15 RPM |

| B axis | 10 RPM |

| Accuracy | |

| X,Y and Z axes | 0.010mm (0.0004”) |

| A and B axes | 0.00550 (20 arc seconds) |

| Repeatability | |

| X,Y and Z axes | 0.008mm (0.0003”) |

| A and B axes | 0.0040 (15 arc seconds) |

| Laser System | |

| Fiber laser | 1070nm wavelength 50 - 100 Watt average power Q-switch pulsed - 100kHz |

| Beam Delivery System | |

| Scanning head | X and Y via mirrors Galvo-motor driven Focal length 163mm (6.4”) Typ. Spot size 75 microns (0.003”) |

| Control System | |

| PC based platform | Windows 7® operating system |

| Axis drives | AC motors Direct absolute encoders |

| Operator interface | Machine pendant |

| Machine mode selection | Manual, auto, MDI etc. |

| Machine manual control | Touchscreen or pushbuttons |

| Part program editing | Via touch screen |

| Pushbutton functions | Start, hold, reset, E-stop |

| Keyboard | QWERTY |

| Camera | Through lens display |

Applications

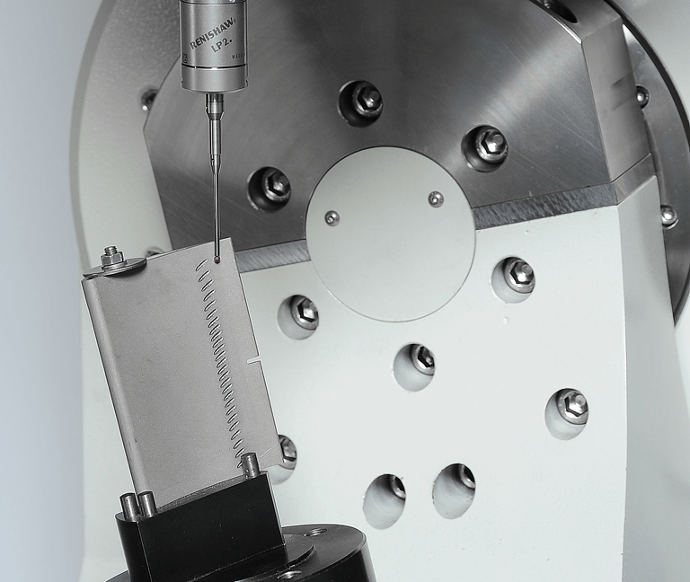

- 2D & 3D diffuser shapes (in coated or uncoated parts)

- Localised removal of TBC

- Reopening of blocked cooling holes

- Side by side with HS EDM drilling

(Laser ablate the diffuser and EDM drill the meter hole)

Features

Winbro Group has installed over 250 of the acclaimed HSD series machines across the world into the most advanced aerospace and land based gas turbine industries. Developed from the original specification for these machines, the HSA5-III encompasses the latest design, control and process concepts. Enhanced features of the machine include:

- Windows 7® based operating system

- Patented Part Probing

- Integration of a range of fiber based lasers

- Winbro LaseMill software

The HSA5-III is built upon a robust fabricated steel base which is welded, stress relieved and machined.

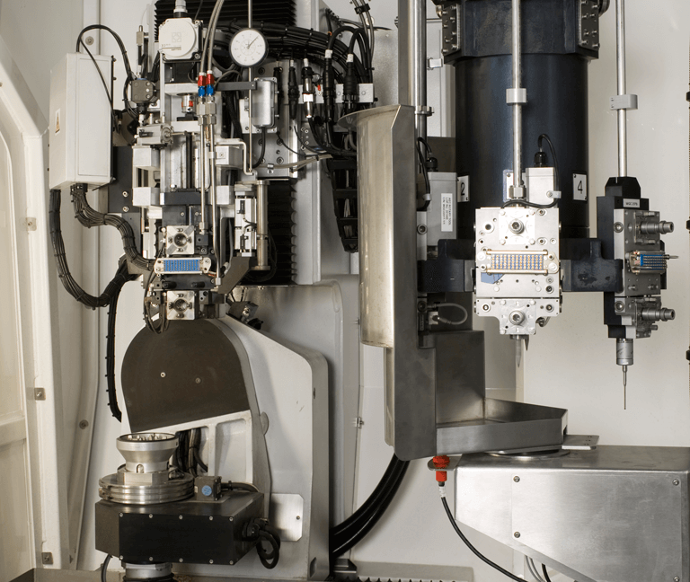

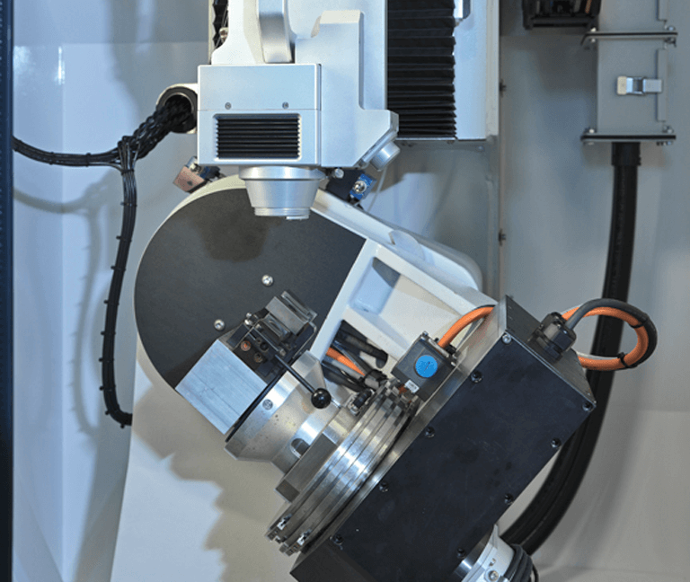

A fabricated column, mounted to the rear of the base carries the Z axis, on to which is mounted the integrated laser scanning head. The “X” and “Y” assembly is mounted on machined pads at the front of the base. The A / B rotary / tilt table is mounted directly to the X-Y table, and driven by torque motors.

HSA5-III machine uses a fiber laser which delivers 50 - 100 Watt of average power, pulsing through a Q-switch at up to 100kHz. A Galvo-Scanning head is used to move the beam on a programmed path with a typical focal length of 163mm (6.4”) and the laser spot size of approximately 75 microns (0.003”).

- Winbro LaseMill software

- Ability to handle file formats: IGES, STEP, NX, STL, CATIA and ProE