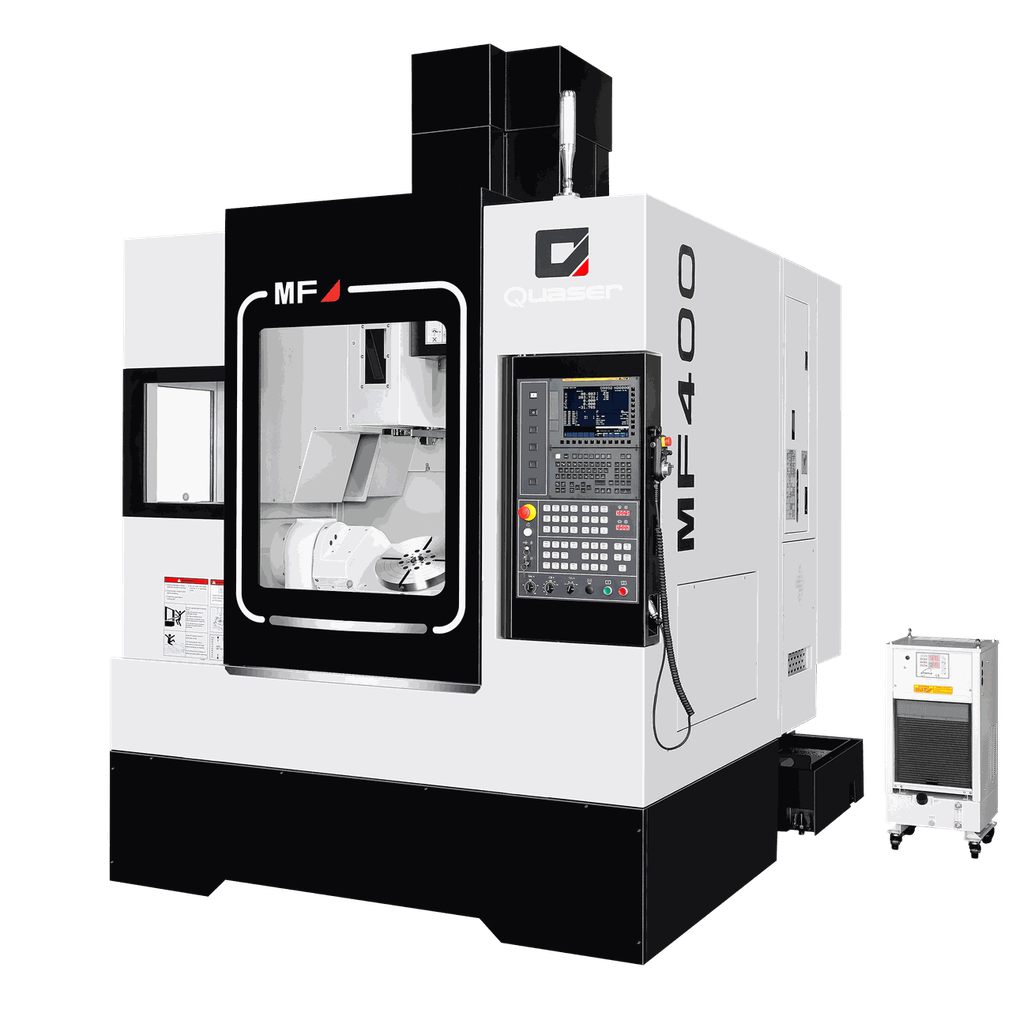

MF400

Multi Face、5 Axes M/C

The high performance MF series multiple face / 5-axis vertical machining centers are for small to medium complex high-quality parts for aerospace, automotive, medical, mold and die applications. From roughing to finishing, the MF series reduces setup time and overall production, while improving machining accuracy, quality and precision.

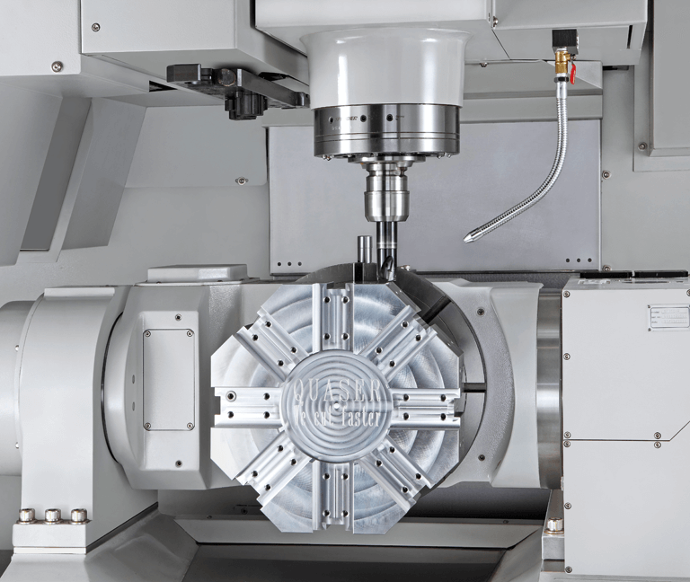

The rotary table is designed to reduce coefficient of friction and strengthen the torque transmission capability of the drive motor.

The symmetrical structure of slide mechanism and rotary pallet allows for higher rigidity.

The MF series is designed for easy operation, even for beginners who have no experience of multiple face/5 axis machining.

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Technical Data | MF400 |

| Work Range | |

| Table Size | Ø320 mm (Ø12.6") |

| Max. Swing | Ø400 mm (Ø15.8") |

| Max. Work Piece Size | Ø400 x 300 mm (Ø15.8" x 11.8") |

| Travel X | 410 mm (16.1") |

| Travel Y | 610 mm (24.0") |

| Travel Z | 510 mm (20.1") |

| Table Load Capacity | 100 kg (220 lbs) |

| Main Spindle | |

| Spindle Taper |

40 taper

|

| Max. Spindle Speed | 12K ~ 20K |

| Tool Changer | |

| Magazine Positions | 30 (std.) |

| Max. Tool Diameter | 76.2 mm (3") |

| Max. Tool Dia. Due to Neighbor Pots Are Empty | 125 mm (4.9") |

| Max. Tool Length | 280 mm (11.0") |

Applications

Automobile, aerospace, medical, mold & die…industries.