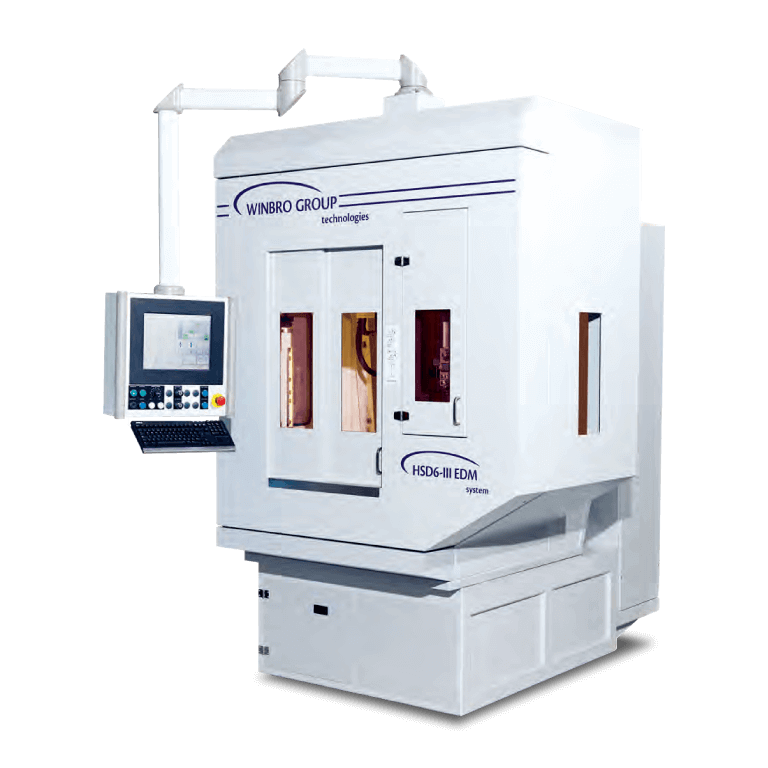

HSD6-III

EDM

The HSD6-III High Speed EDM System offers industry leading performance whilst maintaining stringent aero and IGT metallurgical requirements. It can accommodate component dimensions of 225mm x 225mm x 225mm (8.85 x 8.85 x 8.85 inches) and with a payload of 10kg (22lbs).

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Type | HSD6-III |

| Strokes | |

| Linear X | 200mm (7.87 inches) |

| Linear Y | 200mm (7.87 inches) |

| Linear Z | 250mm (9.84 inches) |

| Rotary A | +/- 185° |

| Rotary B | 135° + 100° |

| Rotary C | +/- 8° |

| EDM axis | 100mm (3.94 inches) |

| Accuracy | |

| Linear | 0.010mm (0.00039 inches) |

| Rotary | 20 arc sec |

| Repeatability | |

| Linear | 0.008mm (0.00032 inches) |

| Rotary | +/- 15 arc sec |

Applications

The acclaimed HSD6 machine in its latest MK-III incarnation,has been specially developed for machining cooling holes and slots on Aero and IGT turbine blades, vanes, segments and other components of a similar size.

- Round holes/Shaped holes (oval)

- Seal slots

- 2D & 3D diffusers

Features

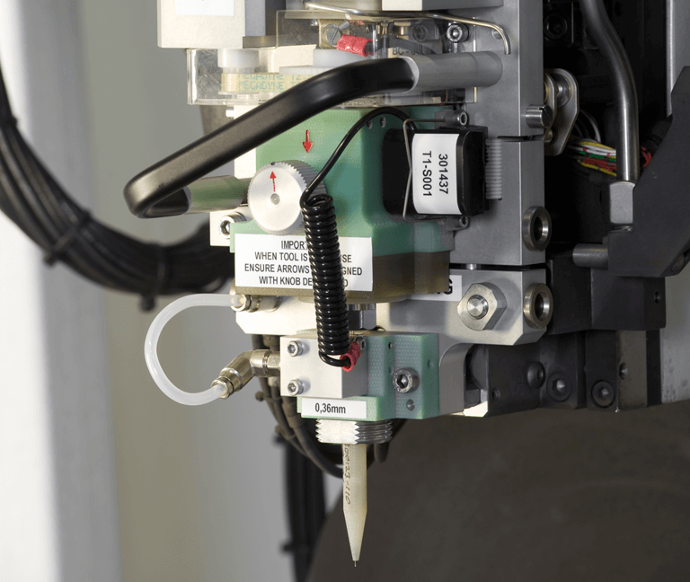

Monitors real time drilling performance.

Reduces the requirement for manual inspection.

Generation of complex 2D and 3D diffuser holes.

Up to 5 times faster than conventional EDM.

From 0.3mm to 3.0mm diameter and up to ~ 100mm in depth.

Allows positioning using simple fixturing.

Ensures accurate positioning of drilled holes.

Hole true position measurement using a laser opticator.

Single point rotating or static electrode.

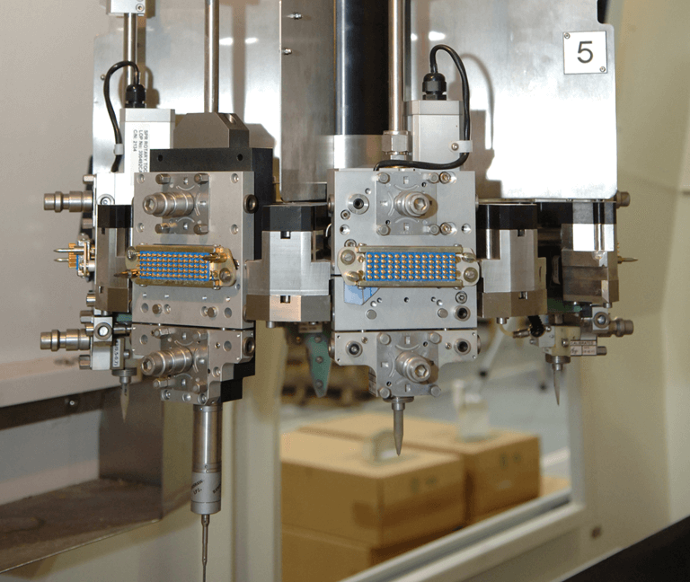

Single AEC (12 electrode automatic changing tool).

Multi-tool with up to 45 individually sensed electrodes.