Energy

Fuel Cells

Lasers are especially well suited to high-speed drilling of fine holes with high aspect ratio.

Drilling rates of *several thousand holes per second have been achieved on precision systems, with high positional accuracy and repeatability.

Hole array drilling is widely used for clean energy applications such as Membranes, Fuel Cells, Battery Cells and Gas Distribution.

Other applications include Nozzles, Sieves, Through Vias, Functional Surfaces and Industrial Press Plates.

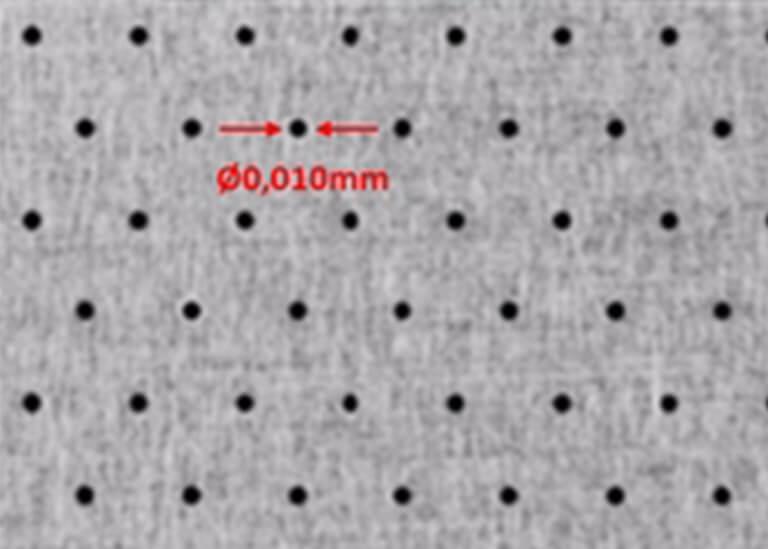

Drilling holes of diameters in the range of 0,010mm (ten micron) and above is possible in a range of materials including specialty metals, super hard materials, semiconductor substrates, ceramics and polymers.

Laser drilling will be accomplished by selecting a specific laser source from a range of products / manufacturers, where the wavelength and pulse characteristics are well matched to your material.

*specific drill rates are dependent on the material composition and dimensions. Please talk to us about your requirements from proof of concept to manufacture.

Case study: Fuel cell membranes

—Twenty-micron hole diameter

—Speciality steel

—High aspect ratio (deep holes) not possible with chemical etchants

—Drilling rates of multiple thousands of holes per second

—Positional accuracy of holes to datum within twenty micron

—Automated workpiece handling

—Simultaneous processing of multiple workpieces

—Visual inspection with high accuracy, superior gauge repeatability and quantitative data analysis