Aerospace

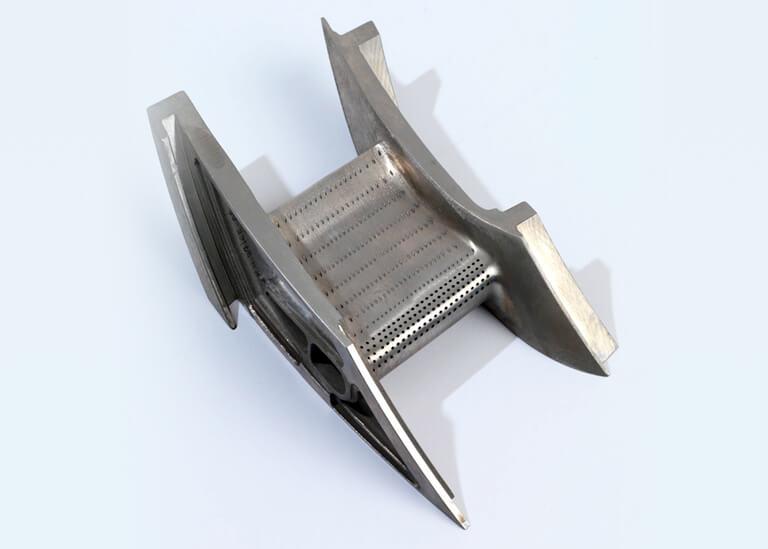

Nozzle Guide Vane

Winbro manufactures machine systems which are used to create the miniature holes required to cool aero and industrial gas turbine high pressure blades. These holes are critical in allowing internal airflow to cool parts and prevent overheating during engine operation. Effective cooling improves component efficiency leading to reduced fuel consumption and NOx emissions on today’s generation of lightweight, low noise, jet engines.

Cooling holes shield components from temperatures that are often higher than their melting point, making their precise design and manufacture a critical feature of the engine. Components are often cast from high nickel and high cobalt alloys to enhance performance and longevity.

Winbro uses different processes to produce cooling holes – EDM, Laser Drilling, Laser Ablation or a combination of these. The choice of these technologies can be influenced by the particular coating applied to the part (Ceramic or Metallic), metallurgy / productivity requirements or component / feature access. Winbro Group Technologies has become recognised as a world leader in the development and implementation of these technologies for the production of cooling holes.

Now with the addition of the FGC 2 creep-feed grinding machine manufactured at Winbro we offer multi axis grinding of features such as fir-tree root forms.