FGC 2

Multi Axis Grinding

FGC 2

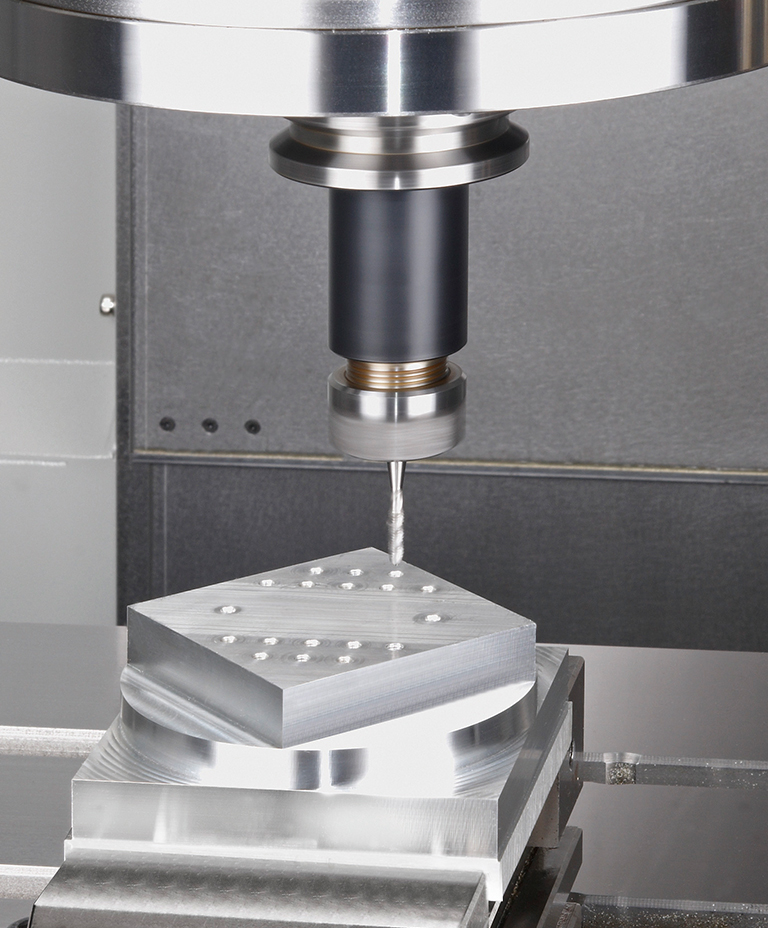

The FGC 2, with its 4 and 5 axis capability allows complex components and forms to be manufactured simply and quickly. Performance benefits include reduced set up time, high part accuracy and fast cycle times.

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Type | FGC 2 |

| Axis Travel | |

| X Axis | 800mm (31.4 inches) |

| Y Axis | 600mm (23.6 inches) |

| Z Axis | 510mm (20.0 inches) |

| Rotary A Axis (rotary) |

360° |

| B Axis (tilt) |

+/-110° |

| Feedrate | |

| Rapid Traverse (X,Y and Z axes) |

32m/min (1,260ipm) |

| Acceleration (X,Y and Z axes) |

5m/sec2 (196 in/sec2) |

| Accuracy - ISO 230-2 | |

| Positioning (X,Y and Z axes) |

A 0.005mm (0.00019”) |

| Repeatability (X,Y and Z axes) |

R 0.003mm (0.00012”) |

| Table | |

| Working Surface | 1400 x 650mm (55.0 x 25.5”) |

| Slots | 7 on 100mm centres (3.937”) |

| Spindle | |

| Maximum Speed | 8,000 rpm |

| Motor HP Rating (S6-60%) |

50hp / 38kW |

| Spindle Taper | BBT40 |

| Control | |

| Heidenhain | iTNC 530 |

| Automatic Tool Changer (ATC) | |

| Type of Tool Shank | BT40 Supplied |

| Tool Storage Capacity | 12 x 250mm (10”) dia Wheels 16 x 220mm (8.6”) dia Wheels |

| Maximum Tool Diameter (milling) | 75mm (2.5 inches) |

| Maximum Tool Diameter (grinding) | 250mm (9.8 inches) |

| Maximum Tool Length (milling) | 300mm (11.8 inches) |

| Maximum Tool Weight | 7.0 kg (15.6lbs) |

| Maximum Weight (all tools) | 200 kg (529lbs) |

| Random Change Time (Tool to Tool) |

3.5 seconds |

| Random Change Time (Chip to Chip) |

8.0 seconds |

| Coolant and Chip Management | |

| Pressure (Grinding) |

40 bar (580 psi) |

| Pressure (Wheel Cleaning) |

70 bar (1,015 psi) |

| Coolant Flow (Grinding) |

120l / min (31.7 gal/min) |

| Coolant Flow (Wheel Cleaning) |

100l / min (26.4 gal/min) |

Applications

- Turbine Blades - Shrouded and Shroudless

- Compressor Blades

- Nozzle Guide Vanes

- Heat Shields

Features

01Diamond Roll Wheel Dressing

The FGC 2 machine features both profiled diamond roll and rotary diameter disk dressing capability, providing quick and efficient set up. The machine can also be supplied with a double dresser capability for multiple and extended machining operations, providing even greater productivity levels. The dressing facility enables the economic and precise dressing of complex fir tree root forms and shroud end features - from initial profile dressing through to in-cycle wheel dressing.

02High-Pressure / High Coolant Application

Coolant is supplied by a unique, fully programmable / steerable twin nozzle arrangement. This assures that coolant is continually supplied as near to the cut as possible and that the wheel is always clean and sharp. Results suggest a saving of 30% on wheel life compared to a standard, single nozzle type machine.

03Coolant Filtration System

The FGC 2 grinding centre can be supplied with a unique media-free coolant filtration system. This system is both environmentally friendly, highly efficient and helps reduce operational and overhead costs. This media-free option totally eliminates filter paper consumption.

04Automatic Wheel Change

We understand the need to maximise productivity in a high pressure manufacturing environment. The FGC 2 machine therefore has an automatic wheel change capability which keeps productivity high and wheel change related downtime low.

05Unique Grinding Software

Easy to use, operator friendly and simple to program 3,4 and even 5 axis simultaneous machining of components using on screen graphics. This also includes the positioning of the programmable twin coolant nozzle system.