HSD351

EDM

HSD351

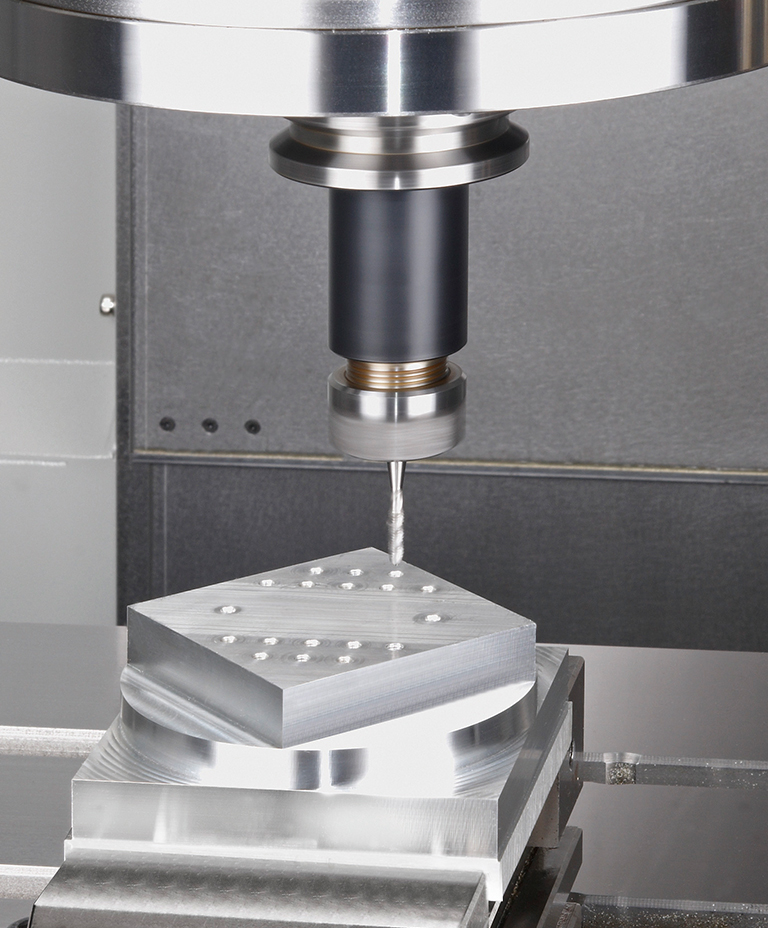

The HSD-351 is the latest development from Winbro Group Technologies and offers a highly compact solution to high speed single point EDM drilling operations.

Quaser Group provides technology and application expertise to enable the best manufacturing performance

| Type | HSD-351 |

| Strokes | |

| Linear X Axis | 300mm (11.81 inches)*410mm for ATC |

| Linear Y Axis | 350mm (13.77 inches) |

| Linear Z Axis | 550mm (21.65 inches) |

| Rotary A Axis | + 10°/ - 143° |

| Rotary C Axis | + / - 360° |

| Accuracy | |

| Linear axes | 0.008mm (0.00032 inches) |

| Rotary axes | 20 arc sec |

| Repeatability | |

| Linear axes | 0.006mm (0.00024 inches) |

| Rotary axes | 15 arc sec |

Features

01NEXT GENERATION OF PROVEN WINBRO TECHNOLOGY

- Cost Control: advancing proven technology, but reduced cost by integration into the machine.

- 24 & 49 electrode cartridge - quick, simple change.

- Automatic electrode change - fast: (<15 sec) spit, load, qualify.

- Single sealing & Single collet covering electrode range from 0.25mm - 3.0mm diameter (0.010” - 0.118”).

02Automatic Toolchanger

- Twin 14-Station carousels.

- Automatic Barrel Changer (ABC).

- Barrels hold 15, 25 or 49 electrodes each, up to 700mm (27.5”) long.

- Automatic Nose Guide Changer (AGC).

- Nominally holds up to 13 nose guides & 1 probe.

03Auto Part Chuck Integrated to Rotary

- Erowa pneumatic flat chuck (standard).

- 10kg (22lb) capacity (fixture & part).

- Chip reader for fixture identification.

- Single & multi-blade fixtures (depending on size).

- Part flushing.

04New Generator

- Solid State EDM Generator (Air-cooled).

05Intuitive User Interfacesystem

- Simplified programming via TCPro and TCPost.

- Part model visible to operator during machining.

- Graphical feature selection for rework.

06Automation Ready

- Machine designed with automation in mind.

- Front or top load/unload.

- Cobot / AGV solutions.

07Digital Ready

- OPC-UA or MT Connect interface options.

- Key Performance Variables monitored in real-time.

- DAX – Data Acquisition system: records detail of each feature.

08Part Life

Serial number control: Track the progress of each component at each machining operations by serial number.

Intelligent factory: Know exactly what operations have been completed on each part & when.

Damage limitation: Prevent unplanned re-machine a feature that is already complete.

096 Point Probing

On machine Renishaw probe enables accurate, automated machine calibration.

Cost control: keep fixtures simple and low cost.

MP250 Rengage probe carried on AGC carousel.

10Integrated Electrode Flow Meter Options

Monitor & record water flow in electrode, nose guide & part before drilling.

11Electrode Verification

On machine quill position check/verification.

Minimise True Position deviation.

11Signature Analysis (including: Breakthrough Detection)

Backwall impingement control (class leading: as proven on HSD6).

Infinitely variable parameter selection during each feature based on user definable criteria.

13Shaped Hole Capable

Advanced shaped-hole generation with high production rates.

Generation of complex 2D and 3D diffuser holes to design intent.

14Auto-Recovery / Recut

Graphical user interface enable operator to see part in 3D, manipulate and identify feature requiring recut.

Recut an incomplete hole automatically.

Machine can recover automatically from interruption mid shaped hole at the exact point it stopped.